| ||||

|

| |||

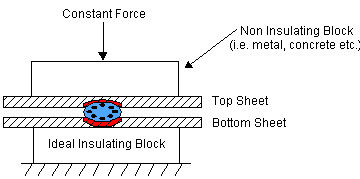

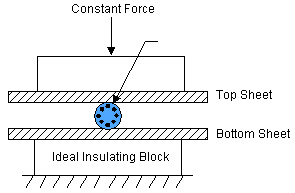

Clamping Thin PlasticsWhen welding thin material, the size of the molten weld zone compared to the size or thickness of the material must be taken into consideration. The molten weld zone can penetrate up to 3/16" (4.7mm) around the Powercore Welding Rod into the plastic material. As in the case of thick material the parts must be held in a static position during the entire weld cycle. However; with thin material, the molten weld zone will come in contact with the clamping device. The clamping device must be constructed so that it will not stick to the weld zone after it cools, and does not conduct the heat away from the weld zone during the weld cycle. The diagrams below illustrate the formation of the molten weld zone between an insulating, and non insulating clamping locks.  The Powercore Welding Rod is positioned and clamped between the top and bottom sheet. (see Simple Weld)

When the weld cycle begins, the Powercore Welding Rod becomes molten and it will begin to flatten.

If a non insulating material is used, heat will be conducted away from the weld zone, and a poor bond may result. The Ideal Clamping Block:The ideal clamping block for thin sheet is made out of some surprisingly common materials. To prevent the block from sticking to the weld zone, masking tape is an excellent material. It has high heat resistance, its inexpensive, and easily removed. Wool Blanket (genuine wool) is an incredible insulating material. It can withstand very high heat, and it is pliable and durable. A dense form is used so the block will conform to the weld zone during the weld cycle. The block is constructed with a ridged base of plywood. In this case a constant force can be applied with a mass (or a clamp) that will give an average weight of .25 psi over the entire clamping block surface. Materials such as rubber or silicone can also be used as an insulator, but these materials can conduct heat away if they are too thick.

The Ideal Clamping Block For easy reference, we have provided all the above information in PDF format for you to download. | |||

| Privacy Policy | Copyright ©2005 Powercore International, Ltd. |