Simple

Weld

Step 1:

After electrical connection pins are inserted (see Stripping

Overview), the welding area and the Powercore Welding Rod must be wiped clean

of any dirt and contaminants. We highly recommend 97% pure isopropyl alcohol,

as it is a pure cleaner that leaves no residue. Acitone, Varsol, or other industrial

cleaners are NOT recommended.

Remember; plastic can oxidize, as steel can rust. It is also recommended that

the area be scuffed with a light sand paper or abrasive cloth to remove this

oxidized layer. This will ensure a very strong bond.

Note: Your hands have dirt and oils on them. Touching the Powercore, and weld

area after they have been cleaned may re-contaminate.

Step 2:

Powercore Welding Rod is positioned, and pre-attached to the bottom

part.(see Positioning Powercore)

Note: Cleaning Powercore and weld area after it has been attached to

part, is recommended and can save time.

Step 3:

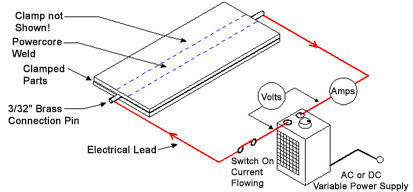

The parts are aligned and clamped together.

(see Clamping

Thin Plastics)

Step 4:

Once positioned and clamped, the electrical leads are connected, and

the power supply is turned on for a pre-determined amount of time

to allow parts to thermally fuse together.

Note: After the power supply is turned off, the parts should remain

clamped together until weld area cools.(1 to 3 minutes depending on

thickness).

A section 0.060" (1.53mm) thick HDPE sheet matirial welded with

Powercore Welding Rod.

For easy reference, we have provided all the above information in PDF

format for you to download.

|